Please contact us for more details.

| Thickness Of Matrial: | 0.3-0.8 Mm | Forming Steps: | 15 Steps/14 Steps/13 Steps |

|---|---|---|---|

| Name: | Metal Roof Making Machine | Usage: | Steel Roofing And Wall Panel |

| Color: | As Required | Voltage: | As Required |

| High Light: |

IBR Sheet Three Layer Roll Forming Machine, Three Layer Roll Forming Machine 15 Steps, Glazed Tile Roll Forming Machine 15 Steps |

||

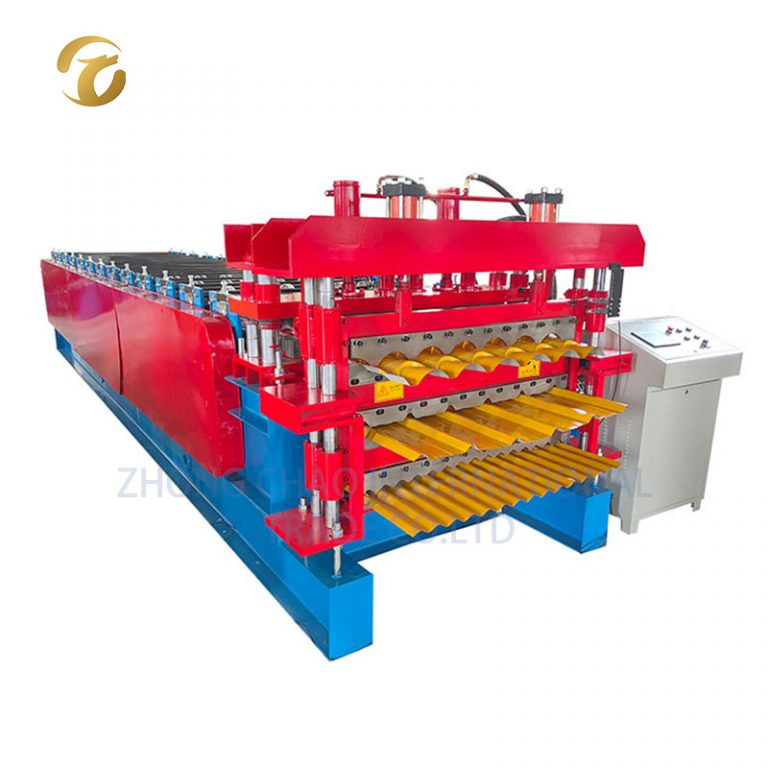

High quality glazed tile IBR sheet three layer trapezoidal roof press making machine roll forming machinery

Three Profile Sheet Combination Three Layer Cold Roll Forming Machine for Roofing and Wall

— One machine have three layers rollers.

— We design the rollers according to customer’s requirement, tell me the profile you want.

— A hydraulic motor instead of the electric motor, the machine working speed is dobule time of before.

— The steel we adopted for machine is GB standard, ensure machine have a long working life.

Three Profile Sheet Combination Three Layer Cold Roll Forming Machine for Roofing and Wall parameters

|

High quality glazed tile IBR sheet double layer trapezoidal roof press making machine roll forming machinery

|

||||

|

1.Formed Material

|

PPGI,GI,AI |

Thickness:0.3-0.8mm

|

||

|

2.Decoiler

|

Hydraulic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

15 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Double Chain transmission

|

|||

|

Dimension(L*W*H)

|

7500*1600*1600(customize)

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Main Power

|

5.5KW

|

||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

8-12m/min 15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

| Machine Components | ||

| No. | Name | QTY |

| 1 | Manual uncoiler | 1 set |

| 2 | Feeding and leveling device | 1 set |

| 3 | Roll forming system | 1 set |

| 4 | Hydraulic punching and cutting | 1 set |

| 5 | Product support frame | 1 set |

| 6 | PLC Control System | 1 set |

FAQ

Q1. What’s your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine.

If the broken parts can’t repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.