Please contact us for more details

Product information:

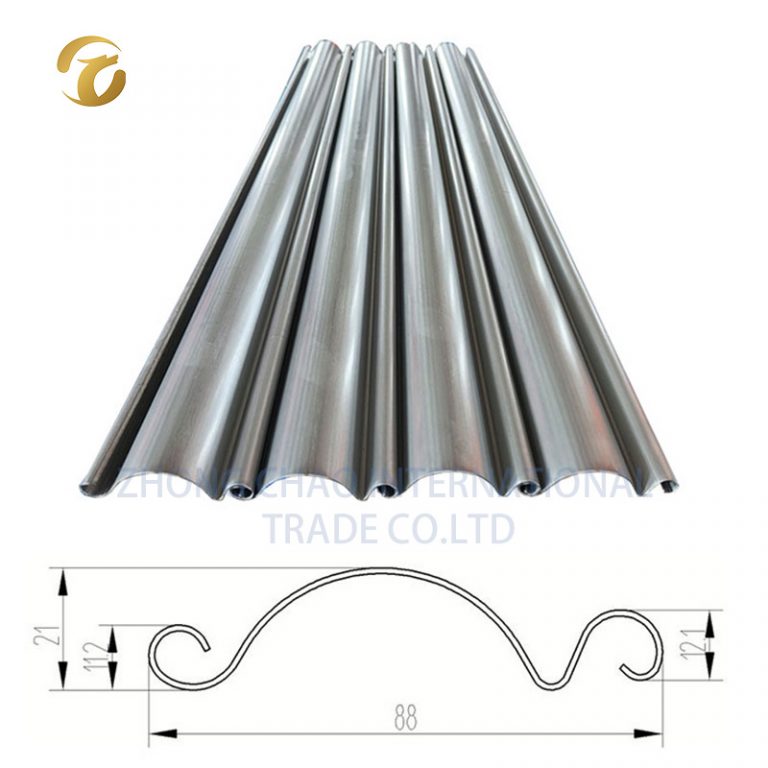

Roll shutter door forming machine have the effect of horizontal isolation, normally used some places without wall. Roll shutter door forming machine is applicable to commercial facade, garage, shopping malls, factories and mines enterprises and so on public place or residence.

Components of roll shutter forming machine

This roll shutter forming machine consists of manual/ automatic decoiler, roll forming machine, plc control system, hydraulic part, cutting part and discharge table.

Characteristic

1. Roller shutter door forming machine can prevent rainwater infiltration.

2. Fire resistance rolling shutter door also have function of fireproof

3. High efficiency, energy saving, can be used continuously

4. Roll shutter door forming machine use PLC and inverter controller

5. The straightening device of this roller shutter door roll forming machine can be adjusted to decrease phenomenon caused in the process of roll forming.

|

No

|

Item

|

Data

|

|

1

|

Raw material width

|

140mm

|

|

2

|

effective width

|

88mm

|

|

3

|

Raw material

|

PPGL/GL

|

|

4

|

Material thickness

|

0.8-1.2 mm or customized

|

|

5

|

Forming roller material

|

45# steel plated with chrome

|

|

6

|

Shaft diameter

|

50 mm

|

|

7

|

Forming roll station

|

12rollers

|

|

8

|

Main motor power

|

4 KW

|

|

9

|

Control system

|

PLC control

|

|

10

|

Language

|

chinese , english or as your customzied

|

|

11

|

Machine color

|

red and bule or as your customized

|

|

12 |

Sizes | 4.5*0.8*1.2m |

1. How to get the quotation?

1.1.Give me the profile drawing and thickness,this is the important.

1.2 Other specific requirements is welcome,such as the speed,power and voltage you want.

1.3 If you don’t have your own profile drawing, we can recommend some model types according to your local market standard.

2. Do you have after sales support?

Yes, we are glad to support advice. Our technicians available across the world.

3. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend a lot of time and money in the research and development of equipment and material selection, so that our machine is more automated, more reliable and accurate, and has a higher service life. Our equipment can last for nearly 20 years, and we offer a two-year warranty.

4. What can we do if the machine broken?

The machine will be tested before shipment with coil, ensure everything is ready 2.We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.Both the sale person and technician can give you the service overseas and make training for the workers,the sale person can make translation, so that the installation and training will be more clear and easily.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.