All of our machine are customized. Customer provide the slat details, we design machine according to customer’s requirements.Please feel free to contact us.

Production Process:

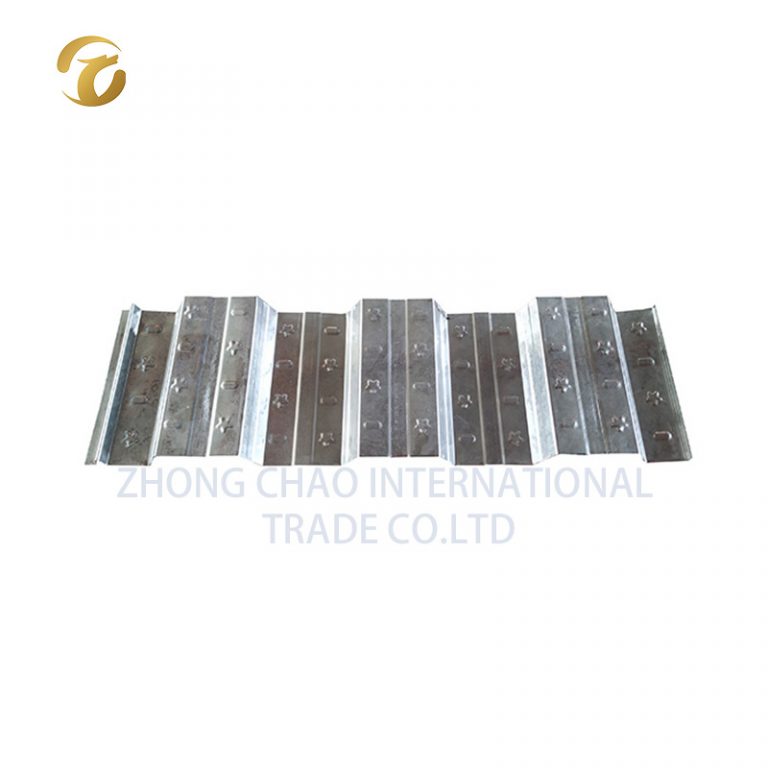

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

Technical parameters:

| Suitable Material | Material | GI, PPGI, PPGL |

| Width | 1220mm | |

| Thickness | 0.8-1.2 mm | |

| Material of rollers | High grade 45# forged steel, surface hard chromium plating | |

| Rows of rollers | 24 stations | |

| Material of shafts | High grade 45# forged steel | |

| Diameter of shafts | 90mm | |

| Material of cutting blade | Cr12 Heat Treatment | |

| Speed | 15-20 m/min | |

| Side plate thickness | 20 mm | |

| Chain size | 2 inch | |

| Total power | 22 kw | |

| Voltage | 380V 50HZ 3Phase | |

| Appearance size (About) | 12000mm*1800mm*1700mm | |

| Weight(About) | 13 tons | |

| Length measurement | Encoder | |

| Control mode | Delta PLC | |

| Operating mode | Button +Delta Touch screen | |

Manual Decoiler

| Capacity | 5T |

| Inner Diameter | 450-550mm |

| Width | 1250mm |

Q: Can you customize the machine from your company?

A: Of course, we can manufacture the machine according to your customized size demand.

Q: How is the quality? Is there any department related to quality control?

A: All raw materials we use are quality controlled. Workers will take care of every detail when handling production and packaging. The quality control department is responsible for the quality of each process.

Q: Is the packaging form?

A: Yes, of course! All our machines will be packaged in dust and water proof, and they can be reinforced after loading to fully meet export packaging standards.

Q: How about after-sales service?

A: TM is online 24 hours a day, and you can also contact them via email, Skype, MSN, whatsapp. and many more Two-year warranty and parts replacement.

FAQ

Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

Q: What size decoiler can you supply us with?

A: From 5-ton decoiler to a 25-ton motorized hydraulic decoiler.

Q: How to visit your company?

A:a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Q: What can you do if the machine broken?

A:Our machine’s warranty period is 12months,if the broken parts can’t repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.