Please contact us for more details.

Galvanized Steel Shutter Door Frame Roll Forming Machine High Precision Cutter

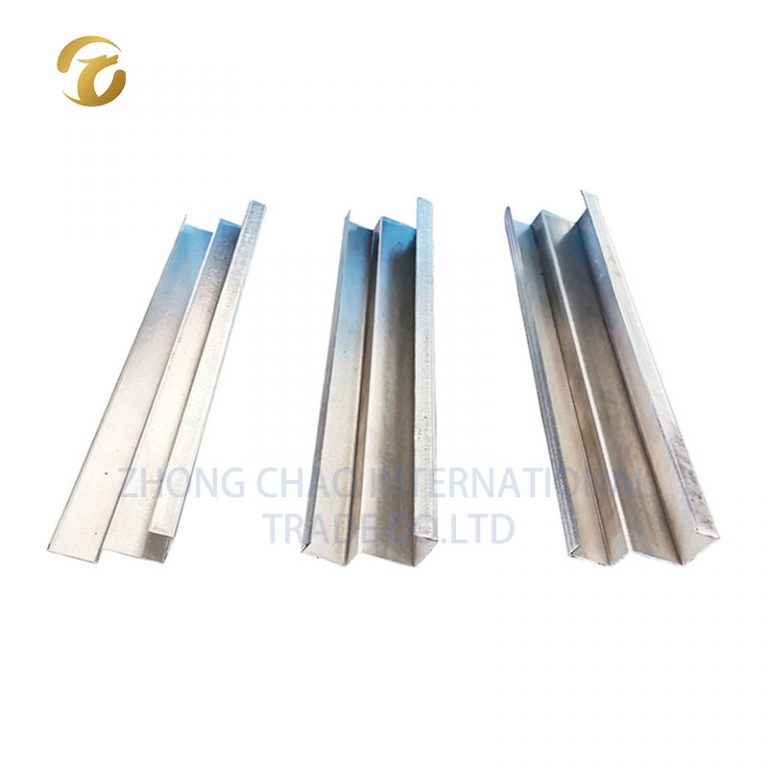

The Door Frames made by our Roll Forming Machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas.

This type of door frames has advantage inclouding beautiful, classical appearance and grace taste.It can be widely used in village, hotel, exhibition, vocation vallage, family construction and outdoor decorate.

Galvanized Steel Shutter Door Frame Roll Forming Machine High Precision Cutter Parameters

A Sheet Specifications

| 1 | Coil Type | PPGI GI |

| 2 | Width | 450mm |

| 3 | Thickness | 0.8-2mm |

| 4 | Yield stress | Q235 |

| 5 | Effective | 300mm |

B Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate | 16mm. We use thicker plates to ensure stability

of our products. |

| Forming Steps | 15, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. |

| Treating process: tempering- finish turning,

high rigidity, hard to deform. |

|

| Cutting

Blade Material |

Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C. Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate. |

| PLC | Delta DVP 14ES |

| well-adapted to various conditions, such as moisture,

electromagnetic disturbance. |

|

| Frequency Converter | Delta VFD-M. It has the advantage of slowing down before cutting,

to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

| Length

Measurement Device |

Omron, made in Japan. |

| It features with high accuracy and stability. |

FAQ

Q1. What’s your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine.

If the broken parts can’t repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.