Please contact us for more details.

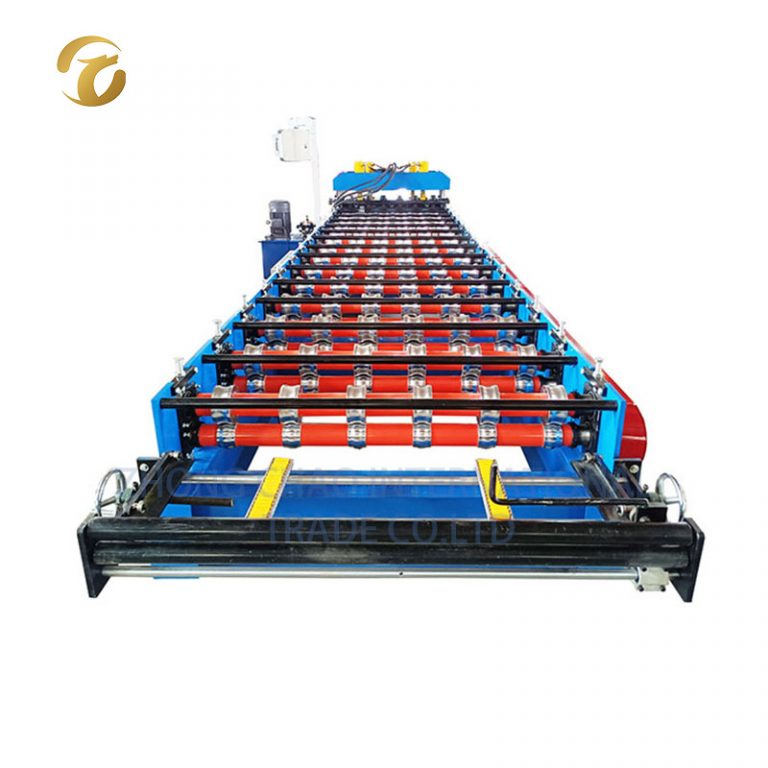

Chain Size 1 Inch Glazed Tile Roll Forming Machine , Profile Sheet Making Forming Machine

1. Usage And Instroduction Of This Production Line

Tile Roofing Roll Forming Machine is able to roll form hardest materials with minimum thickness 0.2 mm. Ameco has three models for Metal Step Tile Roll Forming Machine: Economy, Standard, and Advance.

Regular: Machine with speed driven by proportional valves. (3–3.5 m/min)

High-speed: Machine with speed driven by Inverter and unique hydraulic system. (5–5.5 m/min)

Super-high-speed: Machine with speed driven by Inverter and double hydraulic system. All Rollers are made of high-quality material and gone under Taiwan vacuum heat treatment which makes them stronger. (7–8 m/min)

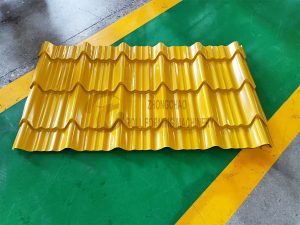

Common Profile: Classic Step Tile Roofing Roll Forming Machine, Master Tile/Prima Tile Roofing Roll Forming Machine, Ruby Tile Roofing Roll Forming Machine (Metepco Step Tile Roofing), Monterrey Step Tile Roofing Roll Forming Machine, Step Tile Roofing Roll Forming Machine, Kiwik Tile Roofing Roll Forming Machine

2. Feature of the glazed tile roof machine

1) Easy in installation and maintenance.

2) Hardened structural steel and components provide long life and safe operational stability.

3) Adopting advanced world famous brand components in controlling parts, electric parts and operation parts.

4) Running in an automation, high durability and stability.

5) Compact design, meet custom demands.

Installation is quick: the light weight composite panels, installation and splicing can be arbitrarily cutting characteristics, determine its simple installation, can greatly improve efficiency, save construction period.

High strength: high strength steel for the substrate (tensile tensile strength 5600KG / CM) coupled with the most advanced design and roll forming, with excellent structural properties.

3. Specifications of the roll forming production line

Control System PLC Delta Inverter

Power Supply 3-Phase,380V,50Hz

Main Frame 350 H-Beam

Main Power 5.5kw

Pump Power 3kw

Forming Speed 10 m/min

Roll Station Upper Level 11 Stands, Down Level 11 Stands

Roller Diameter 70mm

Hydraulic Pressure 10-12 MPa

Forming Size 850mm(852),840mm

Feeding Thickness 0.3-1.2mm

Feeding Width 1000mm

Backboard Thickness 16mm

Chain Size 20mm

Cutter Standard Cr12

Roller Standard Cr12

Cr-Plating Size 0.05mm

Overall Size 7000×1500×1600mm

Total Weight 4.5T

Product packaging

Q1. What’s your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine.

If the broken parts can’t repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.