Clarify specific requirements for the roll forming machine with the client, including specifications, functionalities, etc.

Clarify specific requirements for the roll forming machine with the client, including specifications, functionalities, etc.

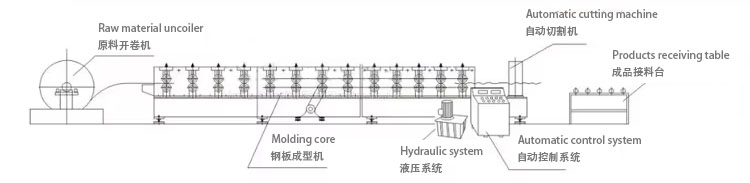

Develop a roll forming machine design proposal based on client requirements, encompassing mechanical and electrical designs.

Procure materials and fabricate the roll forming machine according to the design proposal.

After production, we will have a machine testing to ensure compliance with requirements.

Provide videos and pictures for client acceptance of the machine, making adjustments as necessary.

Ship the roll forming machine via sea freight or other ways, and perform on-site installation and commissioning.

Provide operational training and long-term after-sales support.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.