Please contact us for more details.

Usage And Introduction Of This Production Line

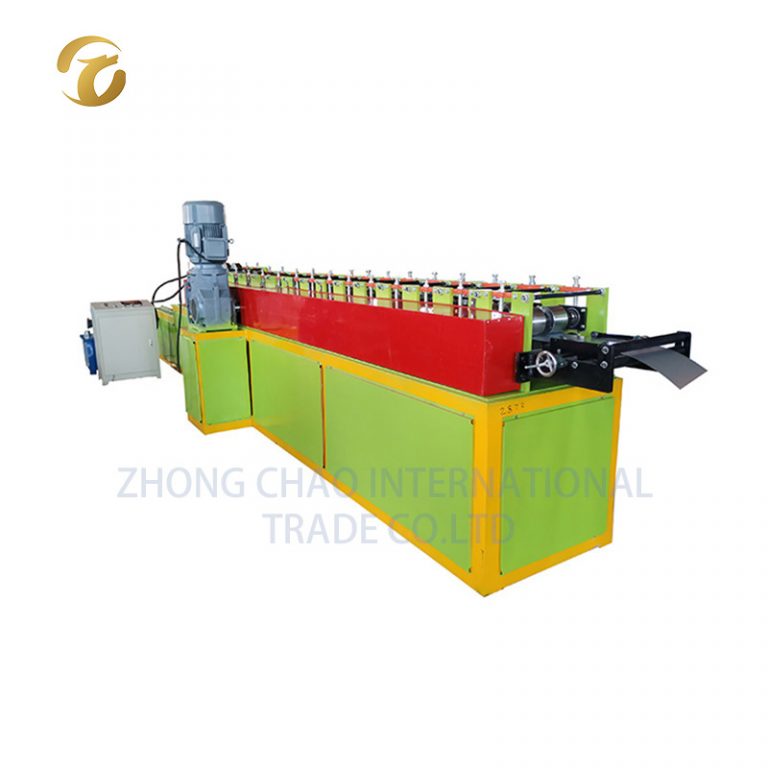

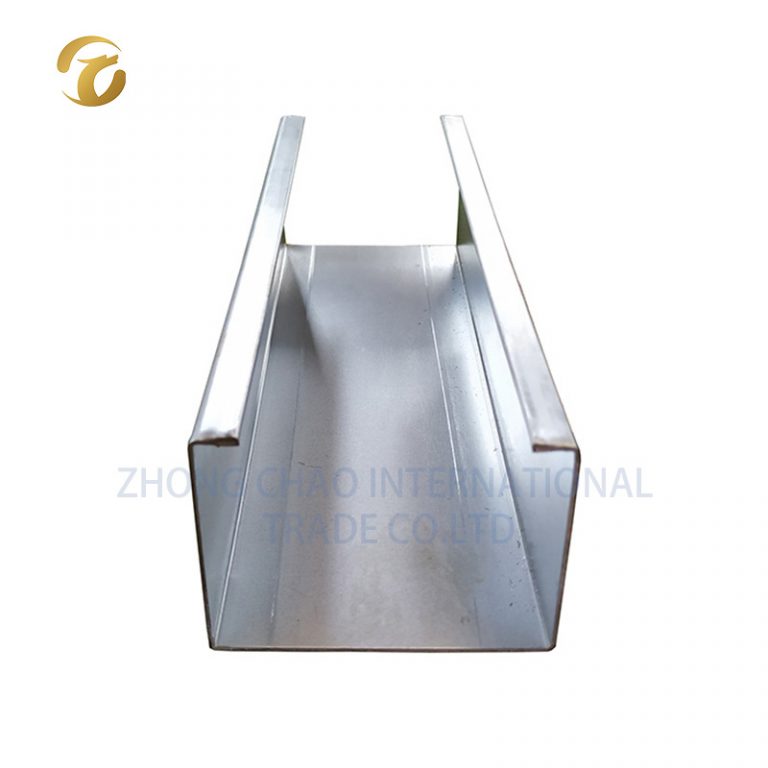

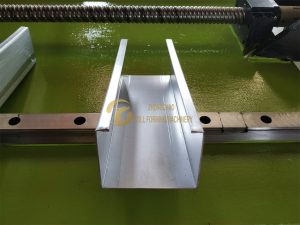

Our roll forming machine can produce different kinds of steel panel products for roof and wall. The tiles is mainly used in temporary building site, steel constructure workshop,and other public building with fast building speed. It has advantage of pretty appearance, durable using and so on.

The metal sheet cold roll forming of us has characters of high spped ,high production, good performance, low labor and save cost. All the above characters are the best selections for producing the metal sheet cold roll form products.

| uncoiler | 1set |

| coil sheet guiding device | 1set |

| main roll forming system | 1set |

| punching device | 1set |

| cutting device | 1set |

| Hydraulic station | 1set |

| PLC control system | 1set |

| support table | 1set |

The roll forming machine parameters

| No. | Metal stud roll forming machine | |

| 1 | Operating Voltage | 380V,50Hz,3 phases or customized |

| 2 | power | 4kw |

| 3 | productivity | 25m/min |

| 4 | Material type | Strip steel |

| 5 | Roller station | 12 forming steps+4 leveling steps |

| 6 | Thickness to process | 0.3~1.5mm |

| 7 | Main Frame | 300H-beam steel |

| 8 | Roller material | Gcr15 steel,quenched |

| 9 | Side-wall thickness | 20mm |

| 10 | Bearing brand | Harbin |

| 11 | Chain | 1.3 inches |

| 12 | Frequency converter | Equipped |

1. Low cost, light weight but high strength, short building period, and re-cycle use

2. Save material , no waste.

3. Easy operation, low maintenance cost

4. Infinite sizing(any size within machine range),help to save material

5. Optional Punch hole at any position of purlin web side and flange side

Some relative terms we can provide:

1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: about 45 workdays

3. Port of loading: port of Xiamen

4. Type of payment: by T/T or by L/C

5. Export: Australia, UK, Ireland, Mexico, Brazil ,Israel ,Dubai, Russia ,India, Taiwan, Singapore,

Malaysia ,Thailand, Philippines, Myanmar ,Vietnam, South Africa, Mozambique,

Zambia, Zimbabwe, Nigeria, Egypt, Sudan, etc.

Packing Method

Main machine is packaged with plastic film

Transportation

All machines need one 20 feet container to hold

Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment.

Delivery Time

Within 35 days after receiving deposit.

Warranty: Two years, and we will provide technical support for wholelife of the equipment. If some parts of machine broken within 2 years, we will give customer the spare parts for free. (include chain, bearing, roller, oil pipe, counting wheel) If more than 2 years, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer.

FAQ

Q1. What’s your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine.

If the broken parts can’t repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.