Please contact us for more details

Product introduction:

Double deck roll forming machine is our factory’s new products. It`s often uesd in the create roof panels or gutters for the purpose of home construction .Double deck Roll forming is a manufacturing process that requires rollers to design something by pressing and rolling it. Our team of technical professionals manufactures this machine by making use of fine grade components with the help of advanced technology in adherence with defined industry norms. To fulfill the diverse application requirements of clients, this Double Deck Roll Forming Machine is offered in a range of technical specifications. Patrons can easily avail this roll forming machine at affordable prices.

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

1. Machine Specifications

| NO. | Item | Parameter |

| 1 | material | color steel/galvanized steel/aluminium(if G550 please check with us) |

| 2 | feeding width | as customers’ request |

| 3 | material thinkness | as customers’ request |

| 4 | machine size | 6.8*1.5*1.9 |

| 5 | machine weight | 5.5T |

| 6 | voltage requirement | 380V60Hz3P |

| 7 | working speed | 10-18m/min |

| 8 | machine base | 350# steel welded |

| 9 | Frame | Steel plate screwed |

| 10 | forming steps | 11steps |

| 11 | rollers | 45# steel with quenching |

| 12 | shaft | 45#steel,diameter 80mm |

| 13 | transmission | 1inch chain or gear |

| 14 | PLC | Delta |

| 15 | motor | 4kw |

| 16 | pump | 4kw |

| 17 | cutter | Cr12 HRC 58-62℃ |

| 18 | after-sale service | 24h*7days*1year’s on line and engineer service overseas |

| 19 | warranty | 1year |

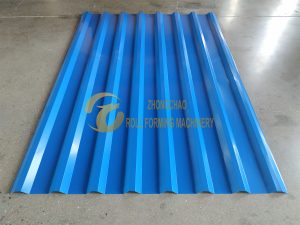

2 Machine pictures

3. roll forming machine company profiles

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. Business terms:

Packing Method

Main machine is packaged with plastic film

Transportation

All machines need one 40 feet container to hold

Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment.

Delivery Time

Within 35 days after receiving deposit.

Warranty

Two years, and we will provide technical support for wholelife of the equipment.

If some parts of machine broken within 2 year, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 2 year, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer.

5. FAQ(about our roll forming machine)

1. Q: How to visit our company:

A: Fly to Beijing Airport: By fast train From Beijing South station to Cangzhou west station

(1hour), then we can pick up you to factory(40min).

Fly to Shanghai Airport: By fast train From Shanghai Hongqiao station to Cangzhou west station(4.5 hours), then we can pick up you to factory(40min).

2. Q: What should I provide if I want to customized machine?

A: U need provide profile drawing, material, thickness, voltage and your special requirements.

3. Q: What is the Warranty?

A: Within 12 mounts, all technicals are ready to serve you at any time.

4. Q: What can you do if the machine broken?

A: Our machine’s warranty period is 12 months, if the broken parts can’t repair, we will send new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

5. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including visa, round trip ticket and suitable accommodation, also buyer should pay the salary 150 USD/day.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.