Please contact us for more details.

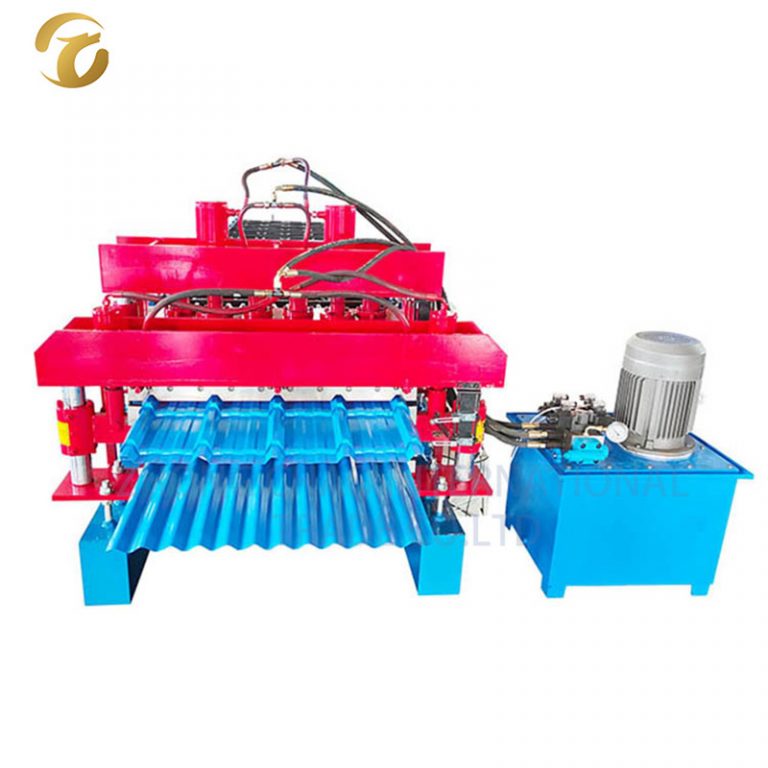

double layer roof roll forming making machine with price

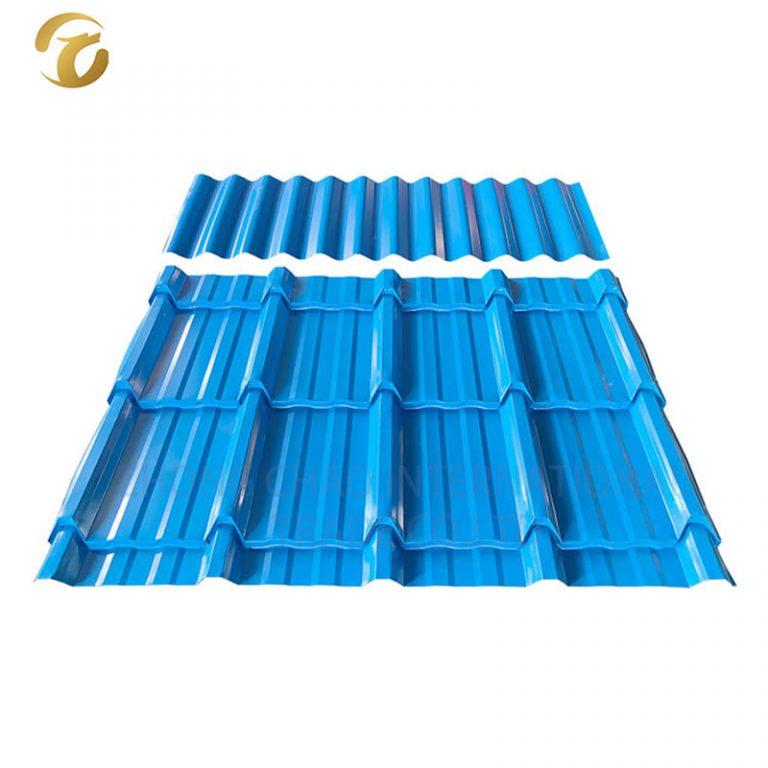

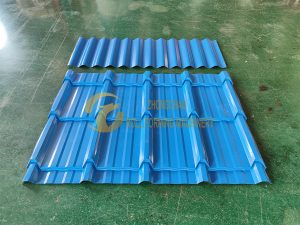

Double layer roofing tile machine: can produce two type sheets, one corrugated sheet and one IBR sheet. The input material are both 1200 mm width with thickness 0.3-0.8mm. Machine speed 20-25 m per minute. With pre-cutting device and double inches chain. This machine cheaper and stable. Widely used in South America zone. Expecially Bolivia. We can also supply you the PPGI and GI coils. We know some good supplier. We can put the coils with the machine in the same container.

Processing Flow Diagram of Machine:

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

Technical parameters:

| Suitable Material | Material | GI, PPGI, PPGL |

| Width | 1200 mm | |

| Thickness | 0.3-0.8 mm | |

| Material of rollers | High grade 45# forged steel, surface hard chromium plating | |

| Rows of rollers | Up layer : 10 stations

Down layer : 13 stations |

|

| Material of shafts | High grade 45# forged steel | |

| Diameter of shafts | 70mm | |

| Material of blade | Cr12 Heat Treatment | |

| Cutting Mode | Hydraulic Guide Column | |

| Speed | 15-20 m/min | |

| Side plate thickness | 16 mm | |

| Chain size | 1 inch | |

| Total power | 4 kw | |

| Voltage | 380V 50HZ 3Phase | |

| Appearance size (About) | 6000mm*1500mm*1600mm | |

| Weight(About) | 4.5 tons | |

| Electronic control system | PLC + Touch Screen | |

Standard Configuration:

| 5 tons Manual decoiler | 1 set |

| Main roll forming machine | 1 set |

| Hydraulic pump system | 1 set |

| PLC control system | 1 set |

| Receiving Table | 2 sets |

| Spare parts | 1 box |

LCL Loading Packaging: Steel pallet and plywood case.

——FCL Loading Packaging: Steel pallet with plastic film.

——Shipping: by sea

FAQ

Q1. What’s your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine.

If the broken parts can’t repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

We are one of the best cold roll forming machinery and equipment manufacturers and suppliers in China.